Why Valcomm?

Valcomm offers a comprehensive suite of solutions to help you navigate the complexities of regulatory compliance, ensuring that your business remains competitive and compliant.

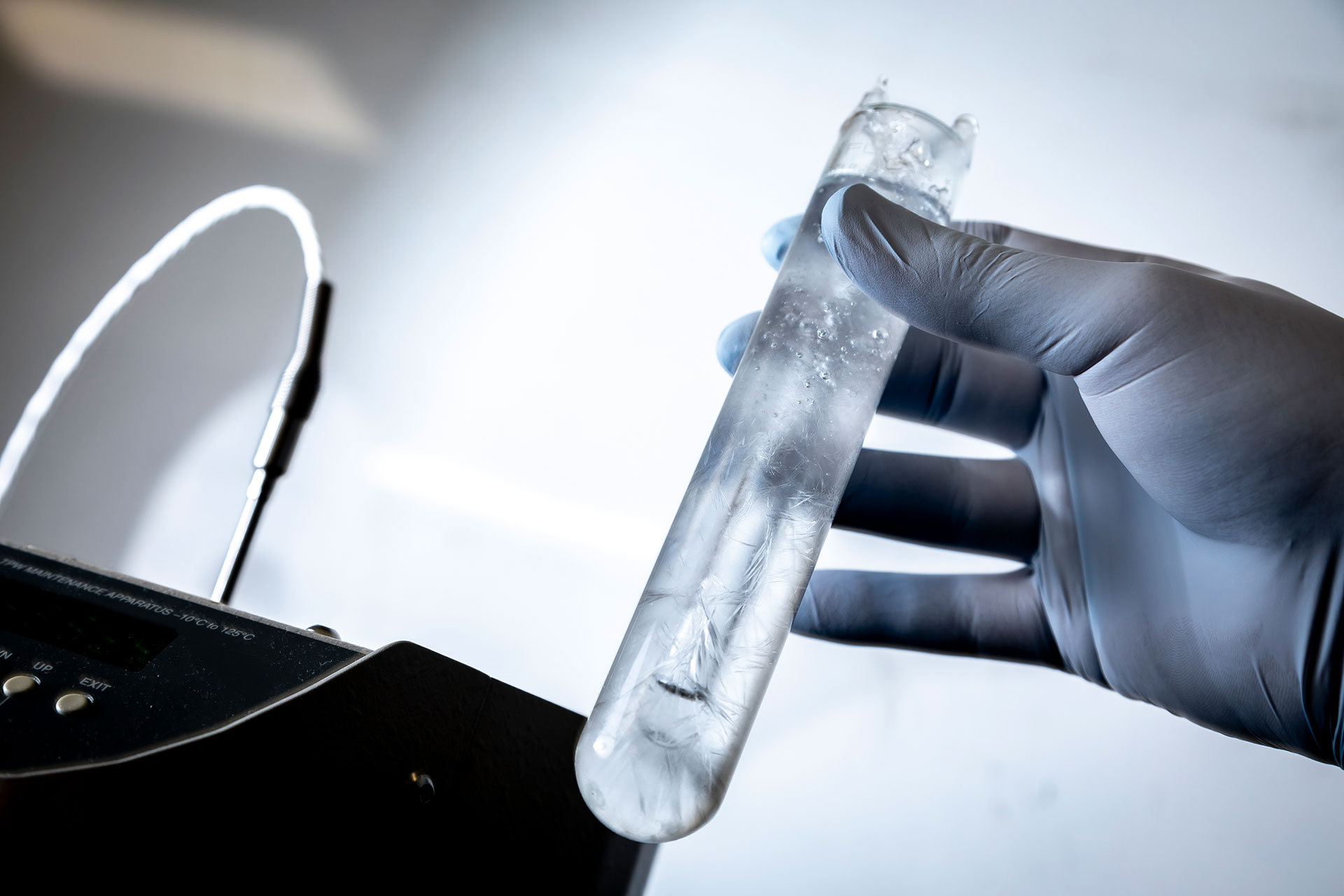

At Valcomm, our meticulous attention to detail and wealth of industry-specific expertise help to ensure our clients remain compliant within their regulated industry. This is critical in the life sciences industry, where fields such as biotechnology, medical devices, biomedical technologies, nutraceuticals and cosmeceuticals require stringent accuracy.

Our services

Qualification and Validation

Achieve your goal of operating a compliant and validated business with Valcomm’s comprehensive qualification methodologies. Our expertise covers everything from straightforward documentation to complex process qualifications, ensuring your operations meet the highest standards.

Temperature/Thermal Mapping

Temperature/thermal mapping is a critical component of pharmaceutical manufacturing and storage. Accurate temperature control is essential to ensure product quality, prevent spoilage, and comply with regulatory requirements. By conducting regular temperature mapping, life science companies can identify and address potential issues, minimising risks and ensuring the safety and efficacy of their products.

commonSENSE Monitoring System

Our cutting-edge environmental monitoring system, commonSENSE, has been designed specifically for the pharmaceutical, and other highly-regulated, industries. Our wireless sensors, calibrated to UKAS ISO 17025 standards, provide real-time data on temperature and humidity, ensuring compliance with industry regulations. With our user-friendly 24/7 portal interface, you can easily monitor and manage your environmental conditions.

Our calibration services

The calibration of devices used by the life sciences industry is critical for ensuring accuracy and standardisation.

UKAS-Accredited Calibration

We are a UKAS-accredited business which means we can evidence the quality of our calibration process via UKAS parameters. It gives our customers the peace of mind that all test results and measurements are correct, and all inspected equipment and processes can be relied upon to operate safely and accurately.

Traceable Calibration

Traceable Calibration maintains traceability within the calibration process. This means any measurement discrepancies can be identified and corrected.

On-Site Calibration

On-site calibration is the process of calibrating equipment directly at its location of use, allowing system downtime, immediate adjustments, troubleshooting and cost savings.